rockwell hardness test applications|rockwell hardness testing instructions : wholesaling Rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load using an indenter. . Step 2: In this step, an additional load is applied over the preload. Here, the test includes the .

web9 de jul. de 2021 · Zwar handelt es sich nicht um eine noch höher angesehene EU-Lizenz, .

{plog:ftitle_list}

WEBXVIDEOS buceta videos, free. XVideos.com - the best free porn videos on internet, 100% free.

rockwell hardness testing procedure pdf

mecurate feuchtigkeitsmessgerät

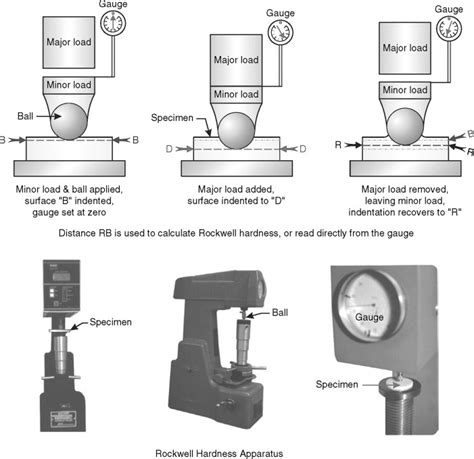

In Rockwell testing, hardness is determined by measuring the comparative depth of two carefully controlled indentations, one superimposed over the other. First . I. What is the Principle of the Rockwell Method? II. What Distinguishes the Rockwell Method? III. What are the Applications of the Rockwell Method? IV. What are the .The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .

In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors .

Rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load using an indenter. . Step 2: In this step, an additional load is applied over the preload. Here, the test includes the .profiles. The Rockwell test is the most popular indentation hardness test and is used in a wide variety of applications. Advantages of the Rockwell Test There are several reasons for the popularity of the Rockwell test. The test itself is very rapid. On a manually operated unit, a Rockwell test takes only five to ten seconds, ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for .this: Rockwell hardness testers are usually less costly than optical hardness testers, the test itself is quick and easy, surface finish of the material is not critical, and the Rockwell scale is a commonly accepted value when purchasing products. Applications for Rockwell Methods The Rockwell hardness test is widely used in various industrial

The Rockwell Hardness Test is the most cost effective method for testing metal applications. 800-486-5546. 800-486-5546. About. About Us; History; Our Team; Blog; Contact; Search Menu. . Metals must often withstand pressure or extreme temperature during its application use, and hardness testing is an ideal way to determine whether the .

Characteristics and Application of Rockwell Hardness (1) This method allows for direct reading of the hardness value and is highly efficient, making it suitable for batch inspection. . The Rockwell hardness test is divided into various scales, each with a wide range of applications. (5) It is important to note that Rockwell hardness values . Application Notes Hardness Testing and Specimen Preparation Hardness testing is a useful tool for the evaluation of materials, quality control of . Figure 8: Schematic description of Rockwell Hardness Testing. Rockwell Formula: Hardness Rockwell HR = E – e. “E” is a constant of 100 (diamond) or 130 (ball) units. “e” is the .Rockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool for

rockwell hardness testing procedure

The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine whether a material or material treatment is suitable for the purpose you require. . The Rockwell hardness test. Rockwell is a fast hardness test method developed for production .For example, a hardness value of 80 on the Rockwell A scale is reported as 80 HRA. Analytical Information. Regular Rockwell Hardness Testing- Measures the bulk hardness of the material. There are separate scales for ferrous metals, nonferrous metals, and plastics. Common Rockwell hardness scales include A, B,C and F for metals and M and R for .The Rockwell hardness test method, as properly defined in ASTM E-18 standards, is the most commonly used hardness test method among all the other methods. . you will need to grasp the workings of the Rockwell hardness testing methods as well as its many advantages and applications. So, if you are ready to know more, then read on.A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .

Rockwell hardness testing applied to measuring the bulk hardness of metallic and polymer/plastic materials and have a wide range of applications. These include: Quality control for metal heat treatment, material inspection, welding evaluations, production evaluations involving alloys, Grade verification for hard plastics, and failure analysis.

Hardness testing is of immense importance for quality assurance in industry. Although the most widely used hardness test methods for metals—Rockwell, Brinell, and Vickers—were developed between 1900 and 1925, numerous technical innovations have been made in recent years, leading to an increase in productivity and the accuracy of hardness tests. The Rockwell hardness test is the most commonly used hardness test in the industry due to its simplicity and accuracy. Brinell Hardness Test: . Applications of Hardness Testing. Hardness testing is an .

The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone .Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that .Guides to Hardness Testing. Hardness Conversion for Rockwell C Scale or High Hardness Range . Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 kgf. .The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine knives. . The key is matching the right steel hardness to the proper application. Professional machine knife .

The downward distance the indenter traveled from the application of the light load to the release of the heavy load is recorded and used to calculate hardness. . Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include:See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .

Rockwell Hardness Test Procedure. The Rockwell hardness test procedure, while seemingly simple, is a detailed exploration of how materials respond to force. It doesn’t just yield a number; it provides insights into how materials will behave under specific conditions, their wear over time, and their performance in practical applications. Selecting the Best Hardness Testing Method for Your Application. The following table provides an overview of various materials, including metals, along with the corresponding hardness testing methods applicable to each. . The Rockwell hardness test involves applying a sequence of loads to the material and measuring the depth of the resulting .Hardness Testing: Principles and Applications is an in-depth study of one of the most fundamental properties of materials and the tools and techniques that have been developed to measure it. Hardness, as defined in the first chapter, is a type of resistance to deformation, the roots of which lie in the packing density of atoms and the bonding forces that keep them in place.Like all ZwickRoell Rockwell hardness testers, these instruments support fast, accurate and efficient hardness testing for a wide range of applications and industries. This testing instrument offers a variety of features that facilitate and optimize your test processes.

The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test parameters. The Right Hardness Testing Method for Your Metals Application The right hardness test method depends on the material being tested and the specific requirements of the application. Understanding the differences among the available options helps determine which method will give you the best results. . Rockwell testers measure hardness based on .

10. 11. 12. 15,945 mulher gozando gemendo orgasmo amador FREE videos found on XVIDEOS for this search.

rockwell hardness test applications|rockwell hardness testing instructions